Stability or comfort?

With most shock absorbers you have to make a choice between stability and comfort… if you opt for stability, you don’t get the smooth ride you’re looking for, but if you choose comfort, you won’t end up feeling as solid on the road. Clearly, it’s best to have both. That’s where VB-AirSuspension’s FSD Shock Absorbers come in.

How standard shock absorbers work

Shock absorbers are essentially oil pumps, with pistons moving up and down in cylindrical chambers containing oil. As the suspension moves up and down, the pistons do too.

Inside the chambers, oil is forced through little holes in the piston, but the holes are so small that only a small amount can pass through at a time, slowing the movement of the piston down and softening the movement of the suspension system.

So, what’s the issue?

The rate of movement in the suspension is known as the ‘frequency’. This frequency varies considerably depending on what type of road-surface you’re driving on.

With the suspension moving at high frequency, you need low damping forces to achieve a comfortable ride, but with the suspension moving at low frequency, high damping forces are required for the vehicle to remain stable. The problem is, most shock absorbers can’t vary the damping forces according to the frequency.

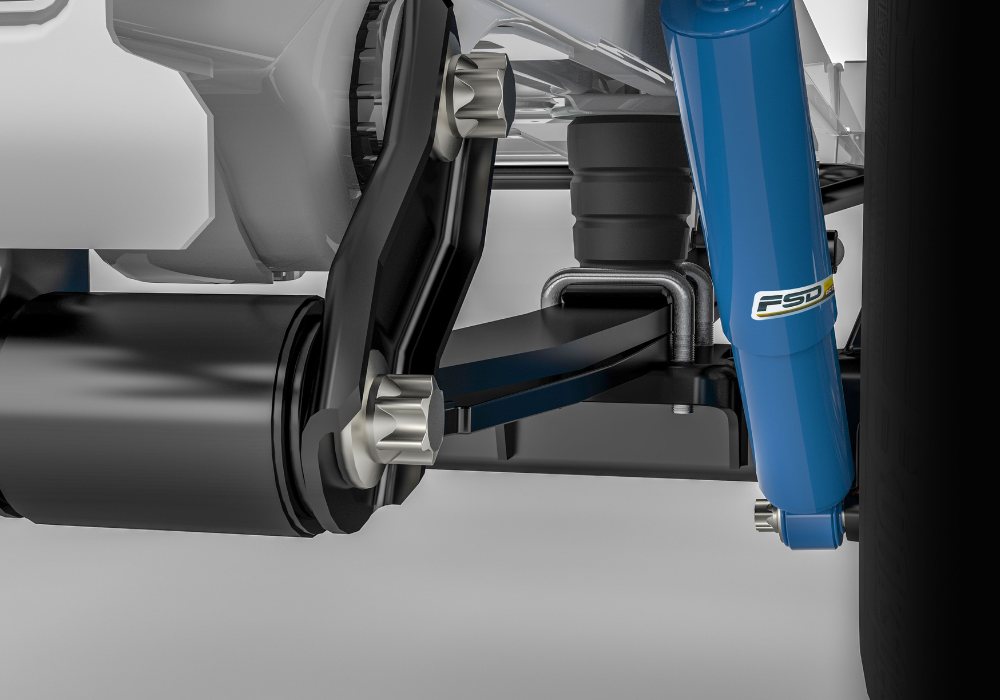

VB FSD Shock Absorbers

As the pistons move through the oil, different pressures are created – and these pressures directly correlate to the frequency. FSD shock absorbers feature a secondary valve that registers these different pressures. This valve controls a parallel oil flow, next to the one going through the piston, exerting a high damping force at low frequencies (to control body roll), and a lower damping force at higher frequency (improving ride quality).

The up-shot? A more comfortable ride, improved stability, greater safety and less vibration from the road… for far less than you’d pay for electronic adjustable shock absorbers.